625

Our services & products

Woodworking

Handling sticks or construction beams – we will find the right solution for your needs. We can supply machinery from infeed of raw material – to packaging of final products.

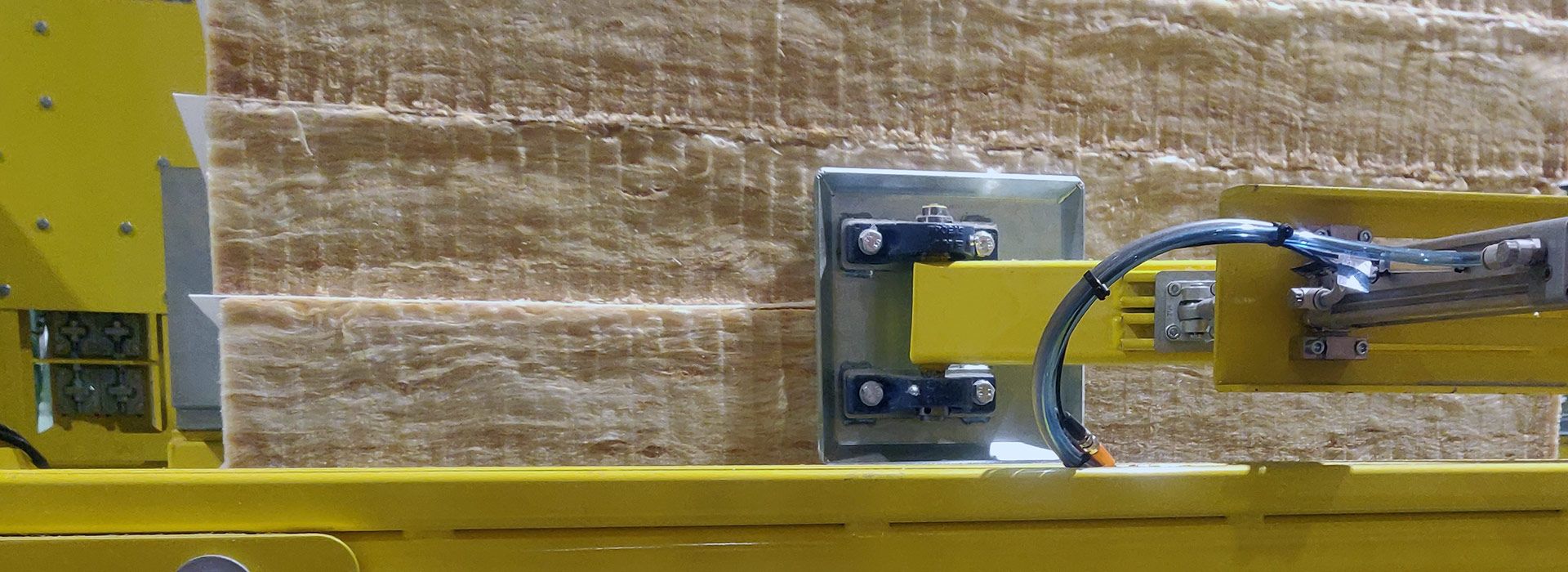

Read moreInsulation industry

Within the insulation industry we have specialized in “cold end” equipment. We deliver cutting sections, line stackers, conveying systems, packaging machines, palletizers, robot systems…

Read moreParquet

We understand parquet production. Our experience with hundreds of projects to the flooring industry, has helped us become a world class supplier of parquet production equipment.

Read more227

Customers

32